Table Of Content

- How to clean an intake manifold in a diesel engine?

- EngineLabs’ Tool Of The Month — DEI’s Fluid-Absorbing Oil Rug

- Intake Manifold Design: Maximizing Performance and Efficiency

- How to Replace Intake Manifold and Its Gasket

- Function of Intake Manifold in Engine

- Components of the Intake Manifold

- Tool Of The Month: Intercomp Digital Torque Wrench Tester

Thus, the PIV system in this study could present the flow characteristic from the relatively large scale of engine dimension to the small scale of turbulence. Another common term for this technology is variable resonance induction system (VRIS).

How to clean an intake manifold in a diesel engine?

Intake manifold porting involves modifying the internal passages of the intake manifold to improve air flow and reduce restrictions. This can lead to increased horsepower and torque by allowing more air to reach the engine cylinders. Remember, upgrading the intake manifold is just one aspect of optimizing the engine’s intake system. It is often beneficial to consider complementary upgrades such as a high-flow throttle body, intake air temperature sensors, and intake manifold porting to maximize the overall performance gains. To illustrate this, let’s imagine two engines with different intake manifold lengths. Engine A has a long intake manifold, while Engine B has a short intake manifold.

EngineLabs’ Tool Of The Month — DEI’s Fluid-Absorbing Oil Rug

Larger-area runners will improve the flow at higher engine speeds, but may also slow the filling of the cylinders at lower engine speeds. Longer runners will sometimes impact the power and torque production at lower engine speeds while shorter runners may move the peak torque rpm higher up. Optimizing the shape and taper angle of the runners will allow maximum performance for a given runner length and area. The shape and size of the plenum should allow for proper pulse-reversion control and a good transition from the throttle body to the intake runners. The pressure fluctuation during intake process of cylinder 1 lagged behind cylinder 2, so the tumble ratio also showed the same trend. In the straight manifold, the tumble developed similar in cylinders 1 and 2 for engine speed 1500 rpm as shown in Fig.

Intake Manifold Design: Maximizing Performance and Efficiency

Intake manifold cleaners generally work effectively in removing carbon deposits and dirt, restoring proper airflow and improving engine performance. However, the effectiveness may vary depending on the severity of the buildup and the specific product used. Regular maintenance and inspection of the intake manifold can help identify potential problems early on. Cleaning the intake manifold periodically can also help prevent carbon buildup and maintain optimal airflow. If you experience any of the symptoms mentioned earlier, it is recommended to consult a professional mechanic for a thorough diagnosis and appropriate repairs. “When I started doing manifolds, I made the conscious decision produce only fully CNC’d items, instead of doing sheetmetal or billet-sheetmetal hybrids,” Steve Morris explained.

How to Replace Intake Manifold and Its Gasket

While billet CNC milled pieces bring an additional amount of cost to the table, the designers and machinists are able to control wall thickness throughout the entire intake. Morris says this minimizes the potential of intake failures, due to a weld failing of in a particular area of the manifold. We have enlisted both of these leaders in the industry on both our Dragzine Project cars.

Function of Intake Manifold in Engine

The inline 6 engine configuration is known for its smooth power delivery and balanced performance. When it comes to intake manifold design for inline 6 engines, there are a few key considerations. By tuning the length and diameter of the runners, engineers can optimize the air flow velocity and improve low-end torque or high-end power. For example, a longer runner length can enhance low-end torque, while a shorter runner length can improve high-end power. The intake manifold is a crucial component in an internal combustion engine that plays a significant role in the overall performance and efficiency of the engine. It is responsible for delivering the air-fuel mixture to the combustion chambers of the engine.

The Performance Design XS Intake Manifold Maximizes Space - Street Muscle

The Performance Design XS Intake Manifold Maximizes Space.

Posted: Tue, 14 Feb 2023 08:00:00 GMT [source]

And Nashiyama and Furui21 found the importance of the spark plug gap velocity near spark timing for GDI engine combustion characteristics using visualization analysis. Raja and Selvam23 found that the intake manifold geometry subsequently affected flow, air–fuel mixing, and combustion. Considering the gasoline engine system characteristics, the intake manifold geometry performance should be analyzed comprehensively taking into account in-cylinder flow and spark plug gap flow. Figure 13 shows the trend of pressure fluctuation for different intake manifold geometry during the intake process. The curved intake manifold cases appear a difference in pressure fluctuations depending on the cylinder during the intake process for all cases.

Does the intake manifold gasket need sealant?

They can assess your specific vehicle and provide you with a detailed breakdown of the costs involved. As mentioned, Morris is also building our 427ci small-block Chevy engine that will power our Fox-body with the help of a Vortech Xi-billet Supercharger. We will have a full-story coming soon on the engine build that will tell you more about the intake and power numbers. Next up is sheetmetal aluminum intake setup, which has been a tried and true intake combination that carries the benefits of a custom designed manifold and a lower hit to the pocket book. Intake manifolds are sometimes made of plastic due to its lighter weight and lower cost compared to metal.

The intake manifold is responsible for delivering the air-fuel mixture to the cylinders, and its design can significantly impact the engine’s power, torque, and fuel efficiency. The geometry of the intake manifold determines the airflow characteristics, such as velocity, turbulence, and distribution, which directly affect the engine’s performance. Factors like runner length, diameter, shape, and plenum volume are carefully considered during the design process to optimize the intake manifold’s performance. By fine-tuning these parameters, engineers can achieve better cylinder filling, improved combustion, and ultimately, enhanced engine performance. In V8 intake manifold design, the primary goal is to maximize air flow and optimize engine performance across a wide range of RPMs.

This modification involves reshaping the intake manifold ports to improve airflow and increase power output. Another benefit of the dry intake manifold is the reduction in intake manifold pressure drop. When the intake air and fuel mix together in a traditional wet intake manifold, the fuel can cause turbulence and restrict the airflow. With a dry intake manifold, the absence of fuel allows for smoother airflow, minimizing pressure drop and maximizing the amount of air entering the cylinders. Edelbrock Sr. knew the engine’s top end was about moving air and fuel to the combustion chamber as efficiently as possible, and a good design had the potential to unlock horsepower.

Remember, the intake manifold is a critical component that significantly impacts the overall efficiency and performance of an internal combustion engine. Now, let’s dive into the process of how the air and fuel mixture is created and distributed in the intake manifold. Kits include a pair of assembled aluminum cylinder heads, an intake manifold, aluminum roller rocker arms, cast aluminum valve covers, and gaskets. If you want to properly control the movement of your engine’s intake and exhaust valves, you’re going to need valve springs. Precise control over valve timing and lift is essential for optimizing engine compression and overall performance, and in high-performance engines, valves open and close at very fast speeds. For that reason, valve springs also play a significant role in maintaining stability within the valvetrain.

The volumetric efficiency was calculated based on the in-cylinder air mass and air density after IVC as follow Eq. Additionally, to visualize the intake flow in the manifold, a transparent manifold made as an acrylic was used. It was difficult to visualize the intake flow in the manifold by using PIV imaging technique because of attached seeds on the surface of the manifold. Therefore, instead of the seeds for PIV, a BnB-1 middle fog was supplied into the cylinder by using a fog machine to visualize the intake flow in manifold.

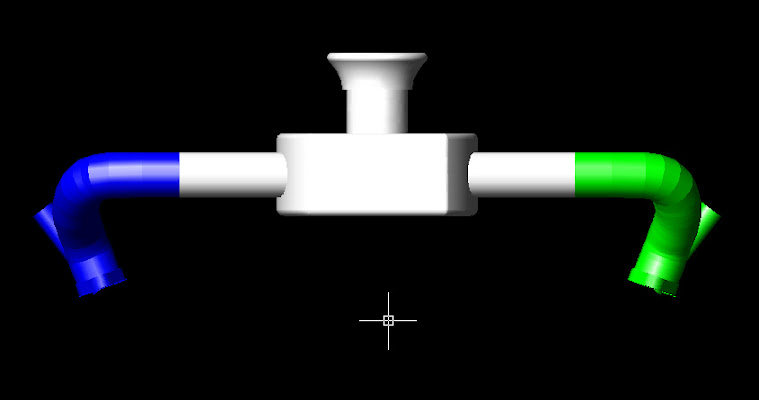

Velocity distribution at intake manifold during cylinder 1 intake process for different intake manifold curve radius at engine speed of 2000 rpm. Figure 21 represents the velocity distribution at the intake manifold during the cylinder 1 intake process. As the intake manifold radius increased, the straightness of the flow inside the manifold is secured along the radius of the curved surface during rapid charging in early intake process. Therefore, it had a faster velocity distribution in the manifold due to a reduced momentum by colliding manifold surface. The intake manifold gasket seals the connection between the intake manifold and the engine block, preventing air leaks and ensuring proper air flow to the cylinders.

No comments:

Post a Comment